|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thermoelectric Cooling Applications |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Things you need to know to start sizing an air conditioner: Temperatures: The ambient is the air temperature around the enclosure, often the room temperature. The enclosure temperature is the temperature range you wish to maintain in the enclosure. The difference between the two is the design temperature differential (delta T). Look at these temperatures with care. What is the real maximum ambient? What is the real maximum enclosure temperature? How can I define these? Ask maintenance or those who work in the area. Look at the temperature specs of the equipment inside. You may want 72 F in your enclosure but is it really necessary? Would 95 F be just as acceptable with occasional excursions to 104 F under worst case conditions? Do not impose unrealistic demands. Heat Loads Active and Ambient: We define an active load as any source of heat inside the enclosure. Waste electric heat or exothermic reactions are examples. This can be determined in several ways. The first is by simply adding up the amount of heat generated by each component. This sounds easy but the information is often not readily available in component spec sheets and requires direct inquiries to manufacturers. A second method is to apply a control volume approach and to measure the total electrical input and output, subtract the two and assume the remainder has been turned into heat. Another method requires knowledge of the thermal characteristics of the enclosure, how many degrees does it rise given a defined amount of internal heat generation. This can be found by monitoring internal and external temperatures and varying a known internal load while bringing the system to equilibrium between each step and recording the values. Use these numbers to determine the degrees per watt enclosure characteristic. Once this characteristic of the enclosure is known the system can be operated to steady state, the ambient and enclosure temperatures measured and a quick calculation made to estimate the amount of internal heat generated. An ambient load is that amount of heat added to the enclosure due to ambient conditions. The usual ambient load is that caused by the temperature difference between the enclosure and the ambient. It is a function of the enclosure thermal characteristics (size, insulation, seals, windows etc…). The same value determined experimentally as described above can be used to estimate the ambient load. Outdoor applications often have an additional solar component. Indoor applications can have something similar if for instance they are in close proximity to a heat source such as a furnace. Performance Curves: The total load and temperature differential (dT) can be applied to the performance curves of the air conditioners to determine if the capacity is sufficient. Complete details on this process can be found on TECA Catalog Page 12. Things you should consider when selecting an air conditioner: Purpose: What is the real need for cooling: maintaining electronics temperatures, precision temperature control, maintaining sample temperatures, cooling a process? Answering these questions will ascertain the need for an air conditioner and help in selecting the control types and methods. Temperature Control: Several control options are available. The most widely used controls are the TC-6F cool only temperature control set to its 35 C setting and the TC-3F heat/cool control. This setting provides a comfortable temperature for the electronics, minimizes chances of condensation and an efficient duty cycle for the air conditioner. For tighter control, air conditioners set up for remote control via an umbilical cord are used in conjunction with TC-3400/3500/4300/4600 or customer supplied controls. These units typically require a 3 to 32 VDC drive signal to turn the heating or cooling on. Buck heating control where the air conditioner is on 100% of the time and control is provided through a separate heater is another option. P, PI, PID and PWM control schemes have all been used with success. There is one caution regarding input surges when trying to get tight temperature control with AC input units. Each application should be evaluated independently to assure safe and proper control. Environment: IP and NEMA both define the types of environments one might find. We’ve included those types of designations with the air conditioners to help you select the right one for your environment. In general our standard air conditioners can handle factory and office environments, “XE” style are appropriate for many wet factory environments and outdoors, “X” style can handle a bit more rugged environment, the “XM” style employ military fans throughout and have been customer tested to survive severe shock and vibration in all axes while “XP” units can handle harsh indoor/outdoor hazardous locations like CI D2 explosion proof. Power Input: Air conditioners requiring 110 VAC, 220 VAC, 110/220 VAC, 12 VDC, 24 VDC and 12/24/48 VDC are available. Inquiries for other inputs are welcome. Cooling Medium: Are you looking for an air (fan) cooled air conditioner (AHP and FHP products)? Is a liquid cooled version appropriate for your application (LHP products)? Perhaps the environment rules out both fan and liquid cooled. Is compressed air available (AHP-CXP products)? Enclosure size and characteristics: How big is it? The bigger it is the more heat it transfers in and out. Is it insulated? Does it have any features that will interfere with mounting an air conditioner? Is it appropriate for the environment? Does it have windows and access ports which will affect the amount of cooling required? Can you protect it from external loads by using solar shades or shields? Will the enclosure, its contents and the air conditioner mesh well together? Air Conditioner Mounting: These air conditioners can be mounted in any orientation, wall mounted is usually best. There are two types of mounting styles available, through mount where the cold side of the air conditioner extends into the enclosure and flush mount where there is no or minimal protrusion into the enclosure. Regardless of which style chosen it is important to orient the air conditioner in such a way that it compliments rather than hinders internal air circulation. Internal fans (cold side fans) typically run continuously to provide a constant internal air flow. External fans cycle with demand. Condensation Concerns: The best time to address condensation concerns is in the selection of the air conditioner. Will conditions be ripe for condensation to occur? Condensation may form on the fins when their surface temperature goes below the dew point temperature. Use the “Cold Sink” equations provided for each product with your total load value in this equation to determine the delta T and therefore the actual temperature of the cold side heat exchanger. Compare this value to the expected dew point to see if condensation might occur. The 35 C setting of the TC-6F temperature control goes a long way in minimizing moisture. Set it to the 25 C or continuous on position and you may be setting yourself up for problems because the cold side fins will get that much colder. Side, front, or back mounting is recommended if there are condensation concerns. Many flush mount units come with condensate control systems which soak up moisture and transport it away. There are drip pan accessories for through mount air conditioners to collect and remove moisture. See page 70 of TECA Catalog, Air Conditioner Accessories for more details on drip pans TIGHT TEMPERATURE CONTROL WITHIN SMALL ENCLOSURE:

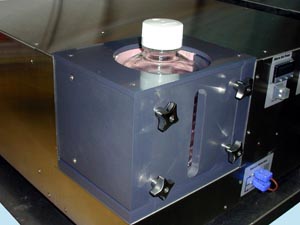

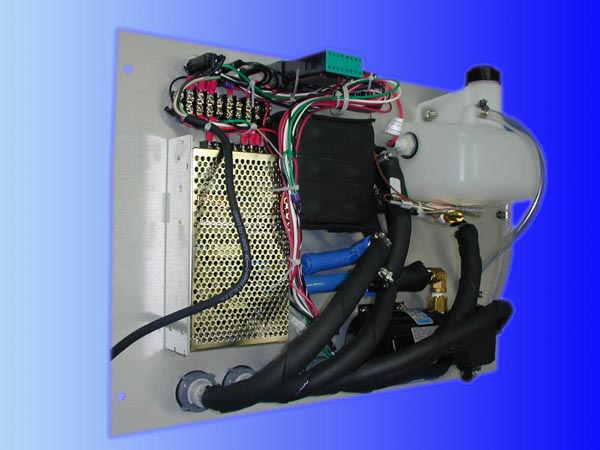

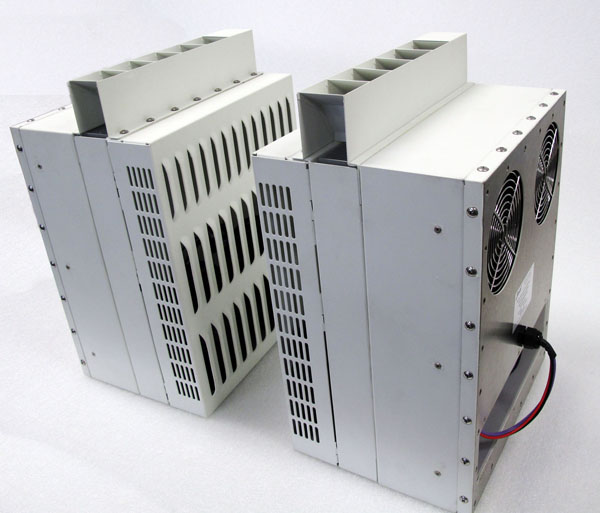

A manufacturer of specialty materials required cooling and heating of small enclosures. The system pictured here is used for the mixing of helium and hydrogen with dew point control. TECA Model AHP-301FFHC is used with a TECA PID temperature controller to regulate the temperature of the enclosure in order to establish the moisture content of the “wet gas”, which is blended with dry gas to fix the dew point by way of the Buck Equation. The customer is pleased with the results and continues to build more systems using TECA air conditioners and temperature controllers. COOLING LARGER ENCLOSURES THAN EVER BEFORE: One of our first customers to buy the AHP-6250 Model Solid-State Air Conditioner gives a wonderful example of the benefit of TECA’s newly introduced line of high-capacity thermoelectric air conditioners. Designed to cool larger enclosures than was previously practical with thermoelectric technology, the AHP-6250 is one of the largest models in this group. For example, the enclosure pictured here is about 8 x 6 x 3 feet. The customer is able to achieve large enclosure cooling with a single thermoelectric air conditioner. Thermoelectric cooling is reliable and maintenance free.

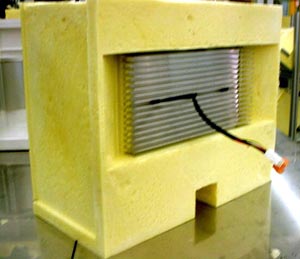

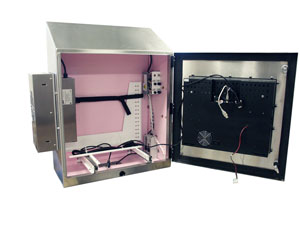

TECA’s new high-capacity line has some thoughtful design features, as seen pictured here on the installed AHP-6250. The cold side (internal to enclosure) has a low profile, which translates into less intrusion into the enclosure, giving the user more room for whatever the enclosure is meant to hold. The robust mounting flange, gasket and hardware and centrally located power input contribute to user-friendly installation. Finally, high air-flow fans and high fin-density heat sinks on the cold side maximize performance and minimize condensation. An integral condensate removal system absorbs condensation and transports it to the hot side, where it gets evaporated into the ambient. COMMUNICATIONS Maintain the temperature of a battery bank in a Class 1 Division 2 explosion proof environment to power portable communications equipment. A special purpose vehicle manufacturer needed to maintain the temperature of a bank of batteries to maintain maximum performance.

With our recommendation, the customer selected the TECA Model AHP1800XP, because it is the only NEMA4X air conditioner available off-the-shelf, which is also certified for C1D2 use. The power source was able to meet the requirement of operation in a Class 1 Division 2 explosion proof environment, to support portable communications systems at car racing venues.

HAZARDOUS ENVIRONMENT: A custom design solution based on a standard thermoelectric air conditioner AHP-1801X was developed to meet European hazardous environment specification (ATEX) for a customer that was in need of such a system in a very short time.

CORROSIVE ENVIRONMENT:

The AHP-1802XPHC-2 met the customers need in an application where other similar products could not function due to extreme corrosive environment. The TECA design team in a short notice was able to provide a solution based on a standard AHP-1800X thermoelectric air conditioner. COOLING MEDDICINE IN TRANSIT:

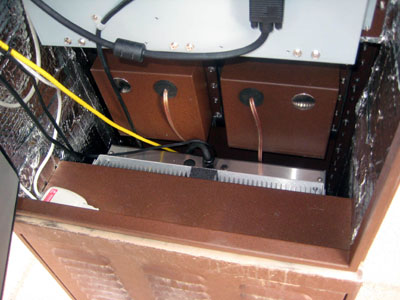

A customer designs and installs custom systems for public safety vehicles. TECA’s AHP-1800-Series Air Conditioner was the perfect fit for keeping medicine cool in transport and in the field. With multiple input voltage and environment configurations available, the customer will be using more TECA air conditioners in other vehicles. The tight mounting space shown in these photos illustrates the value of thermoelectric air conditioners. There are no filters to change, no chemical coolants and there are no moving parts except the fans. The customer can expect years upon years of service from this unit, virtually maintenance free! KIOSK: Pictures below show a 4 year-old outdoor kiosk that is located in a zoo in the Sonoran Desert. The kiosk holds a computer and LCD screen, both generating heat, both mounted within an inch of each other. This active heat load coupled with the high ambient temperatures create a significant need for cooling. TECA's model AHP-1800XE Thermoelectric Air Conditioner has proven to be a reliable solution. Our customer raves “I had zero problems in past years, not even one tech. call. During the summer time here, when outside temperatures reach 95-110F, and surface of the kiosk gets as high as 125F, the LCD, computer and other components were running cooler than the components in our indoor kiosks.”

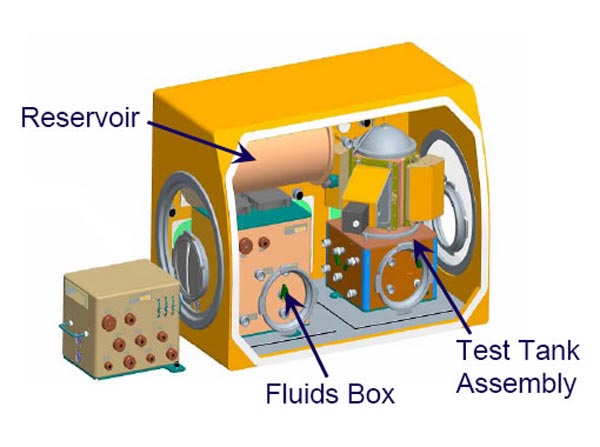

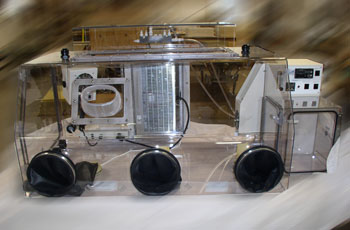

COOLING GLOVE BOXES: A customer manufactures a range of glove box systems for atmosphere control applications in clinical and industrial environments. TECA air conditioners are a vital component on a variety of the glove box models that this customer produces. Standard and customized versions of TECA air conditioners from the AHP-1800-Series are used to control the glove box temperature to below ambient. Clinical applications primarily revolve around cell and bacterial studies within cancer research, bio-fuels studies, sleep apnea, anaerobic microbiology research and clinical applications etc. Industrial applications include product weighing or assembly with humidity and temperature maintenance.

ROBOTICS: An industrial plant uses robots in its juicing and bottling process. The robots continuously overheat and shut off. The environment is dirty and 240 VAC is the only available input voltage. MILITARY: The 2.4 Meter Mobile SATCOM Tactical Terminal (MSTT) is a lightweight, stand alone, trailer-mounted tri-band SATCOM terminal available to support worldwide, quick deployment satellite communications through military and commercial satellites. It also uses a customized version of the solid state air conditioner AHP-1801X. It was designed and qualified for worldwide operation in tactical military environments.

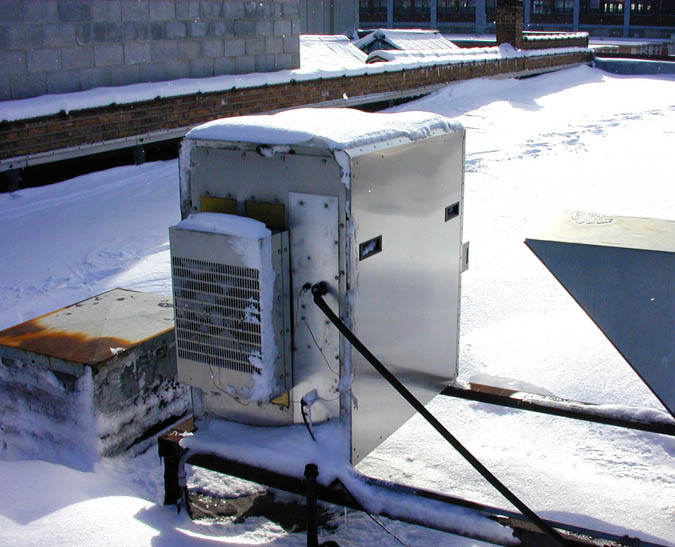

ROOFTOP EQUIPMENT ENCLOSURE:

As of this writing, the system has been operating trouble free for over 90,000 hours. WIND TURBINE: The applications for AHP-1802XE’s are Vestas wind turbines, one located in Greece and one in the south of Japan.

TRUCK PROCESSING TERMINAL:

STEEL MILL: The steel company from Maryland had some enclosures with 4 drives each on some cranes. The high temperature in the steel mill was causing excessive shutdowns. Leaving the enclosure open in this sort of environment just wouldn’t do. Nor would conventional air conditioners survive the shake rattle and bake of the electrical enclosures on these

LARGE LCD SCREENS:

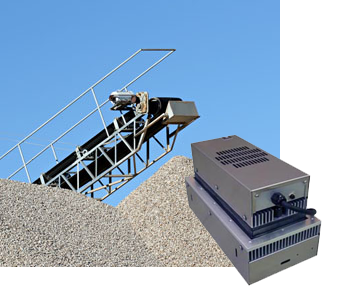

Specializing primarily in the food and beverage processing industries, one of our longtime customers uses TECA air conditioners in several applications. These include cooling or heating LCD screens, desktop computers, thin clients, and KVM kiosks. The locations of these applications are indoors, outdoors, in cold rooms and baking areas. TECA's comprehensive line of air conditioners fit the bills. We offer each model in different configurations according to the customer's need regarding input voltage, mounting and application environment. COAL ANALYSIS: A customer required a constant temperature to keep his detectors working in a coal analysis application. Due to experiencing failures with a competitor's air conditioner, the customer reached out to TECA.

STEEL MILL: The steel company from Maryland had some enclosures with 4 drives each on some cranes. The high temperature in the steel mill was causing excessive shutdowns. Leaving the enclosure open in this sort of environment just wouldn’t do. Nor would conventional air conditioners survive the shake rattle and bake of the electrical enclosures on these overhead cranes. On top of all that the only power they had was a widely varying 250 VDC. Which we found out later had some very nasty spikes which caused everyone a few headaches. But the headaches were cured and the customized FHP-1500XE solid state air conditioners continue to run. How could the company afford custom units? With a streamlined approach where design engineers and the end users actually communicate on a frequent basis with known goals, expectations and commitment from each end. TECA loves happy customers. AERONAUTICS: A leading military and aeronautics contactor needed a cooling solution for an enclosure which would be on a high altitude vessel. The system would be exposed to high winds and ambient elements present in the altitude.

BEVERAGE INDUSTRY EQUIPMENT COOLING:

Our customer manufactures various machinery and appliances for the beverage industry. One such system of theirs requires high performance and precision, achieved by using specially designed software and test & measurement equipment. TECA's thermoelectric air conditioner, the AHP-1200XE with built in temperature controller, is an important part of this system. The customer uses TECA's AHP-1200XE to reliably cool an enclosure housing a computer and touchscreen. The customer has depended on dozens of AHP-1200XE air conditioners over the years for use in their system. INCUBATOR COOLING / INSECT REARING CHAMBER: Incubators used in the rearing of insects for research often experience thermal failures due to the acids inherent in the biology of the insects. The acidic environment that insects create can quickly corrode a standard, compressor-based cooling system- even if its copper coils are coated. High humidity adds to the problem because droplets of concentrated acid will collect on the cooling components. The solid-state nature of TECA’s thermoelectric air conditioners solves this problem offering reliability and virtually maintenance-free operation.

A published life science researcher from a local university contacted us because he experienced several failures from his compressor-based air conditioner units. He is raising flies in an incubator, and requires an accurate set point. The TECA Model AHP-1200 Thermoelectric Air Conditioner is the perfect solution. The air conditioner keeps the incubator to 18C as the customer requested. Using a remote, programmable temperature controller (TECA Model TC-3400) the customer is getting the accuracy he needs and the convenience he wanted from a remote controller. ANALYZER COOLING IN HARSH ENVIRONMENT:

TECA’s Model AHP-1202XEHC Thermoelectric Air Conditioner provides accurate heating and cooling for the customer’s analysis machine. The environment is harsh: it is in a cement plant. The customer’s product quickly analyzes composition of raw materials, allowing for increased productivity. TECA’s AHP-1202XEHC provides reliable thermal management within a harsh environment. The AHP-1202XEHC has an industrial grade sealed fan and sealed hot side components, allowing for frequent wash down (NEMA-4). The solid-state construction is the perfect low-maintenance solution for hard-to-access areas. There are no filters to change and no moving parts except for the fans. TECA air conditioners use robust thermoelectric modules and boast a long service life. PORTABLE SECURITY EQUIPMENT:

FOOD PROCCESSING: A European manufacturer of special equipment for processing fruits and vegetables needed to cool sensitive electronics on their line of produce-processing machines, which sort products by color, size and weight.

RUGGEDIZED MILITARY APPLICATION: Sometimes it just takes a long time to get to the heart of a problem. A ruggedized enclosure for a military video projector caused excessive heat to build up from the high wattage bulb. A more rugged version of TECA's AHP-1200FF thermoelectric cooler / solid state air conditioner is used by military to cool a projector.

PAPER MILL: The environment of a paper mill is hostile to most equipment. Could a thermoelectric cooler stand up to such conditions? This TECA model AHP-1200X was returned to TECA for evaluation, after over 120,000 hours of duty. It just did not seem to cool as much any more. As a matter of fact, it was originally put to work in 1992 cooling an electronic enclosure in a paper mill. The customer was sure it needed to be replaced, but sent it back to us to see if anything could be salvaged. In our inspection we found that the hot side heat sink was fouled with 14 years of newsprint sludge. Once the goop was cleaned out and the fan was free to spin; the unit ran like a charm!

RUGGEDIZED FOOD PROCESSING:

The maker of some of our favorite corn chips used TECA’s AHP-1200X for years in severe hose down environments. They now had a similar requirement where they wanted to minimize any cleaning and were willing to entertain a liquid cooled LHP-1200XE solid state air conditioner. The unit fit into the same area and footprint as its air cooled cousin and provided greater cooling capacity. This customer added a valve on the water inlet to provide water flow only when cooling was required. The units have been in service for years. ALARM ENCLOSURE: The alarm enclosure was for fire safety and switches. The transparent plastic enclosure was supposed to be accessible and secure while being cooled to desired temperatures under some of the harshest conditions, firefighting, where extremes of heat and harsh hose down conditions exist. The enclosure was selected already, load known, temperatures OK. Everything was fine except the closest stock unit didn’t quite fit and it needed a few extra bells and whistles to provide the redundancy needed. Taking the standard FHP-750XE air conditioner design, adding an extra circuit and modified sheet metal was all it took.

LAB MEASURMENT EQUIPMENT:A world's leading international supplier of equipment, controls and parts to glass container industry uses the peltier air conditioner model FHP-750XE in a statistical sampling and lab measurement product. A MiniLab Automatic Sampling installation works in conjunction with the production’s online inspection equipment and a Factory Process Control System. The MiniLab Controller communicates to the Process Control System which then sends a container “request” to upstream online inspection systems equipped with mold number readers. The “requested” containers are transferred to the MiniLab sampling conveyor using container ware selectors.

With broad-based expertise in glass container forming, glass conditioning, gob forming, ware handling, cold end inspection, refractory parts and quality assurance, the company's machines and systems are established as standard products worldwide. The FHP-750 has been working fine for them for years. Reasons for its selection are its reliability and ability to operate in high ambient temperatures.

OUTDOORS KIOSK:

An original equipment manufacturer designed a new outdoor information kiosk and required a small cooling solution, before they could start up manufacturing. WATER QUALITY MONITOR: The system pictured below is used to automatically collect and analyze water samples for water quality monitoring purposes. The system can be powered from the grid or from the attached PV system. The TECA AHP-300 air conditioner is located within the enclosure and is used to keep critical internal components cool during the summer months.

MILITARY COMMUNICATIONS: A branch of the US military had a need for cooling a small enclosure containing a critical voice communication system. The shipboard system had to be resistant to salt water corrosion as well as pass stringent shock and vibration testing.

This unit is a prime example of how flexible Team TECA is when customer needs require customization of standard products.

CPU COOLING:

TECA thermoelectric air conditioner model AHP-150FF, the smallest air conditioner TECA offers, cools an alarm system CPU in a small enclosure. The enclosure is located in the engine room of a ship-docking towing vessel. The ambient temperature can reach +130°F. This is a good example of the versatility and range of TECA products. From a small 90 BTU/hr air conditioner like the AHP-150FF to large 5200 BTU/hr air conditioners like the AHP-6252, TECA air conditioners are suitable for a wide range of applications and environments. SURVEILLANCE: Video cameras needed to function in an environment beyond their rated temperature range. One of our customers wanted to position cameras to observe a process from a location not safe for operators to go. The customer is a rubber manufacturer and the camera location was too hot for the cameras to work in. The customer had the cameras, but had no suitable enclosure, or cooling apparatus.

TECA adapted a tiny air conditioner based on Model AHP150XE to mount to a standard commercial enclosure. The package was completed by retrofitting the cameras with insulation and special cooling units. The design satisfied our customer’s needs to a “T”. LONG-TERM COMMUNICATIONS COOLING, OUTDOORS:

A common use for thermoelectric air conditioners is the cooling of electronics cabinets. These photos show an outdoor communications cabinet being cooled with a system of TECA air conditioners that have been customized for the end user. The units photographed here are over 12 years old, a testament to the reliability of TECA’s thermoelectric air conditioners. Also worth mentioning is the lack of maintenance that thermoelectric air conditioners require. With no moving parts except for the fans, no filters to change and no chemical coolants, TECA air conditioners are an ideal and environmentally friendly solution for remote areas. ELECTRONIC IMAGING:

A leading manufacturer of video cameras and mobile electronics communications for law enforcement needed a dependable thermoelectric cooler.The company had been “thrown for a loop” when their previous thermoelectric vendor admitted that they couldn't meet the delivery promised on a standard cooling assembly. EMERGENCY VEHICLES:

COMMUNICATIONS: A major manufacturer of communications equipment was to go into production of special equipment enclosures, then encountered unforeseen problems with overheating electronics deep inside. The customer wanted air conditioning, but specified that no part of the air conditioner could protrude outside of their enclosure.

TECA designed a little air conditioner inside ducts for hot air exhaust. This way the air conditioner is actually housed entirely inside the enclosure and our customer continues production. NUCLEAR PLANT: To cool equipment used for quality control inspection of pipes in nuclear energy plants.

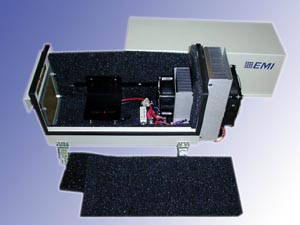

TECA designed, tested and built a system around standard portable cases. The unit shown is the prototype of the production unit, built into the top of a transportation case.

AVIONICS MAINTENANCE: The task was to create a portable cooling system for diagnostic equipment to allow troubleshooting of avionics systems while still installed. Troubleshooting and diagnosing avionics problems is hard enough on the bench. To save valuable time, technicians would rather get it done while the electronics are still in the aircraft. Also, under harsh environments, it is difficult to keep cutting edge electronics functioning the way they should.

When it came to the type of portable cooling for the diagnostic equipment required for these jobs; a navy contractor came to TECA for the solution. We helped design and build the solution shown in its prototype form around the portable enclosure. TECA completed the project on a tight schedule, which called for teamwork and attention to detail.

MILITARY TROOP TRANSPORT:

It was 1994 and a military contractor came to TECA with a problem. COMPACT MILITARY AIR CONDITIONER: The contact to engineering read pretty much like this:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

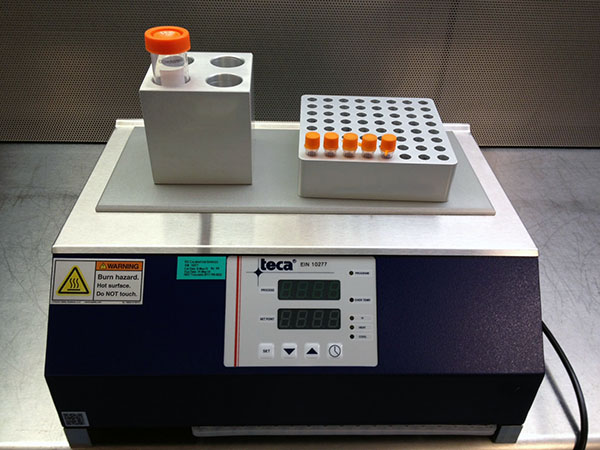

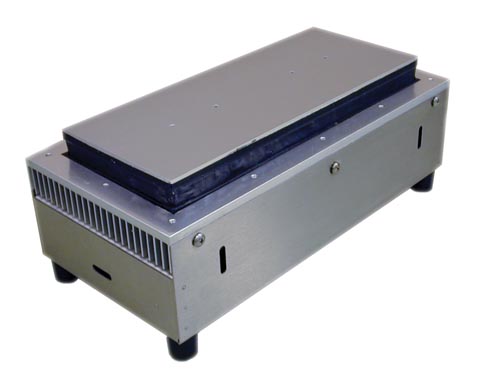

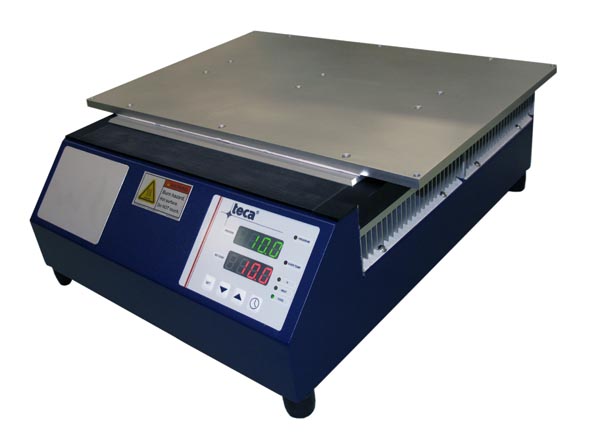

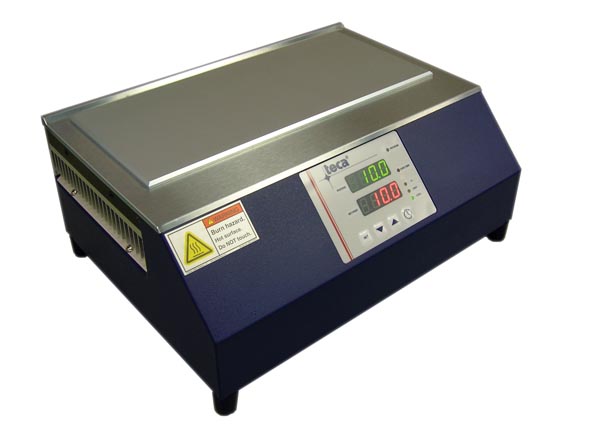

Things you need to know to start sizing a cold plate: Temperatures: The ambient temperature is the air temperature around the cold plate, often the room temperature. The desired temperature can be at the cold plate or at a location on the item being cooled. This means that the cold plate might be colder than the item being cooled. The difference between the two is the design temperature differential (delta T). Make sure to use the cold plate temperature when working with the performance curves. Heat Loads Active and Ambient: We define an active load as any source of heat. Waste electric heat or exothermic reactions are examples. Loads can also be related to the specific heat of a sample when cycle times are important. Ambient loads are caused by the temperature differential between the ambient and the item being cooled. Performance Curves: The total load and temperature differential (delta T) can be applied to the performance curves of the cold plates to determine if the capacity is sufficient. Complete details on this process Things you should consider when selecting cold plate: Purpose: What is the real need for cooling: maintaining electronics temperatures, precision temperature control, maintaining sample temperatures, cooling a process, temperature cycling? Answering these questions will help in selecting the correct cold plate, control types and methods. Temperature Control: Many applications simply require cooling with no fancy temperature controls. The CP style of products often best fit these needs. When better control and more control features are needed the CPV series is often the best choice . Each application should be evaluated independently to assure safe and proper control. Environment: In general our standard cold plates can handle factory, lab and office environments. No standard unit is made for outdoor or washdown environments. Typical locations are bench top, under bench and installed on an enclosure. Custom versions have been made for many environments. Power Input: Cold plates requiring universal input 100-240 VAC, 120 VAC, 240 VAC, 120/240 VAC, 12VDC, 24 VDC and 12/24/48 VDC are available. Cooling Medium: TECA has both air cooled and liquid cooled cold plates. When using the liquid cooled versions the delta T reference temperature is the liquid temperature, when using air cooled cold plates it’s the ambient air temperature. Liquid cooled cold plates require a constant flow of cooling water. This can be tap water, in house chilled water or re-circulating chillers. Mounting: Secure thermally conductive mounting of the componenets to cold plate surface is needed. The CPV versions are bench top units and the standard cold plate comes with no provision for mounting. The cold plate is a smooth flat aluminum surface. Items can be thermally greased into place using DOW 340 heat transfer grease or similar. Many times the tackiness of the grease is enough to hold the test item in place. Side mounting clamps are used with the accessory plate and can also be used with customer plates or loads. If done with care the plate can be drilled and tapped. Refer to the owner’s manual for locations that must not be drilled or tapped. CPV units can also be order with “Tap Plates” installed. These plates have a standard tap pattern on them for customer use. Alternatively a custom tap plate can be ordered plain or with taps, slots, grooves etc per customer requirements. CP versions have a tap pattern as a standard and have provision for mounting to enclosures. TECA's model AHP-1200DCP consists of two adjacent thermoelectric heat/cool plates.

The customer studies whether rats/mice exhibit a significant, temperature-dependent avoidance of plates after injection of analgesic drugs. ANIMAL BEHAVIOR RESEARCH: Investigating the changes in behavioral responses due to changes in experimental floor temperature and dermal application of heating/cooling compounds in an animal model requires precise temperature control system.

ELECTRONIC TEST STATION: An aerospace contractor was interested in a large cold plate for the testing of electronic components. We first offered them the AHP-1200CPV but they responded that the AHP-1200DCP was more the size they wanted. Could we change it to a single plate? Well we couldn’t change the plate size but we could add an accessory plate which was larger. And we could build the unit with one controller including all of the standard options.

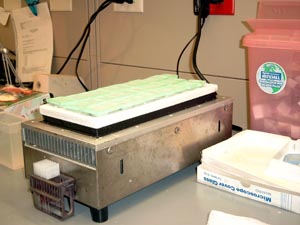

Now they are using the 12” x 18” custom accessory plate and a special AHP-1200DCP to test electronic amplifiers by ramping the temperature up and down between +10 to +70. A custom solution at very nearly standard product price to fill a not so unusual need. Hair Replacement Procedure: Follicular Unit Transplant/Extraction (FUT/FUE) A group of physicians pioneered a hair replacement procedure using TECA’s AHP-1200CPV Cold/Hot Plate. The AHP-1200CPV is a Peltier cold plate. In the photos provided by TECA’s customer, the cold plate keeps hair transplant grafts cool in a solution during the patient’s procedure.

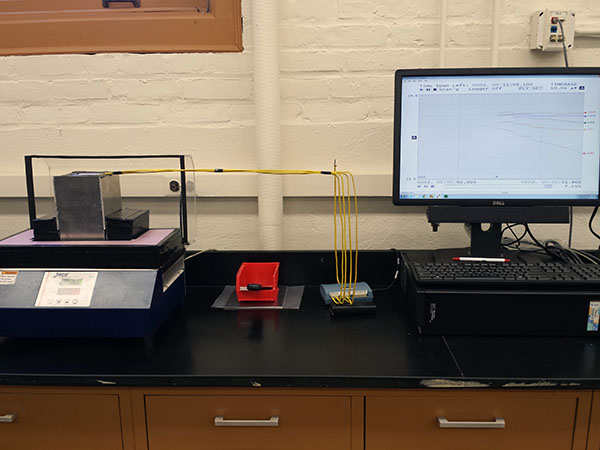

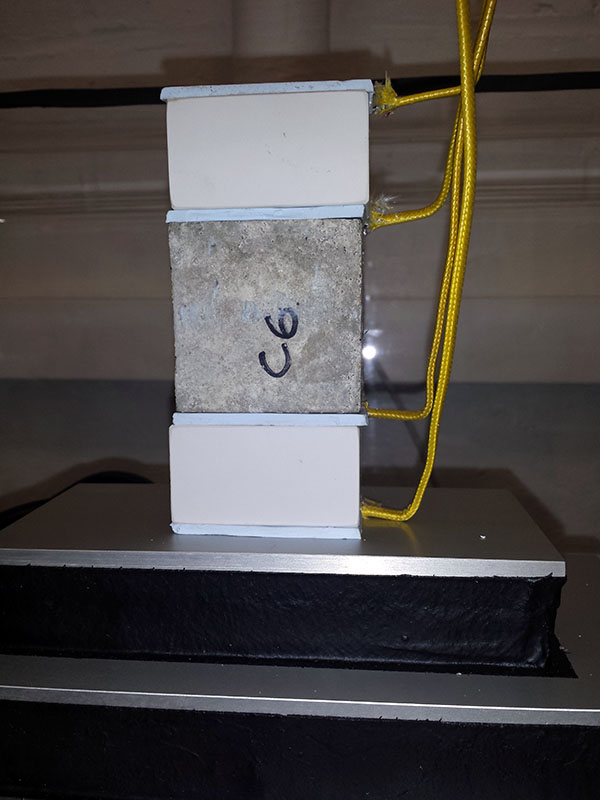

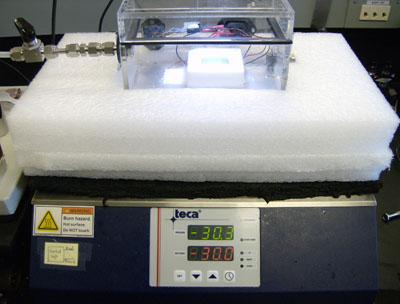

The convenience of the AHP-1200CPV cold plate’s built in temperature controller allows the technician to easily program it to maintain the desired set point. The AHP-1200CPV is capable of reaching temperatures as low as -15C. In the photos here, the set point is programmed to 5C. The AHP-1200CPV has an integral universal power supply, so it can be used with any input voltage range from 100 to 240 VAC. COOLING SAMPLE TO -40C FOR RESEARCH STUDY: A university research team utilized TECA's AHP-1200C31 Cascaded Cold Plate to build a calorimeter for a research paper that was recently published. The researchers aimed to determine the thermal properties of their specimen as part of a study on cement and concrete durability. Originally the customer used only the AHP-1200CAS base cold plate and was able to reach -15C. When he determined that colder temperatures were needed, he added the CCP-31 cascade attachment to reach -40C.

With a cascade system each cascade stage acts as a heat sink for the stage above it. This allows the top stage to reach colder temperatures. TECA offers two and three stage cascade systems for reaching temperatures as low as -60C (LHP-1200C31). COOLING 64 DEGREES BELOW THE AMBIENT: A medical device manufacturer uses a TECA Low-Temperature Cascade System in his design process. The Cascade System consists of a TECA Cold Plate and Cascade attachment. The system offers direct contact cooling to the customer's load. In this example, the customer was able to cool his load of Isopropyl Alcohol solution from +25C to -25C in about 35 minutes.

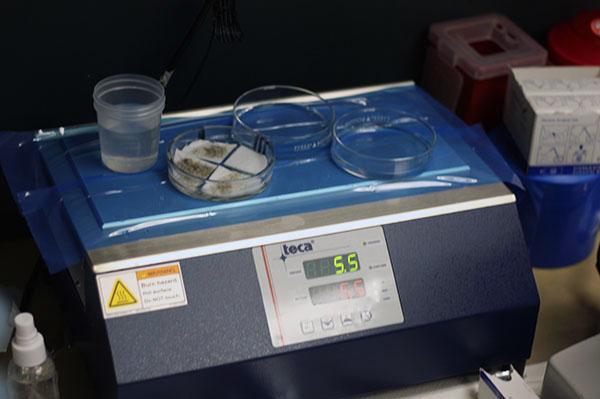

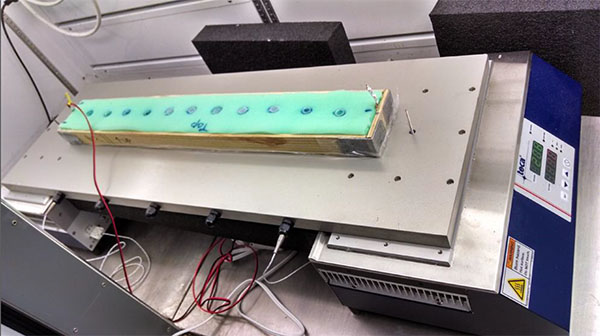

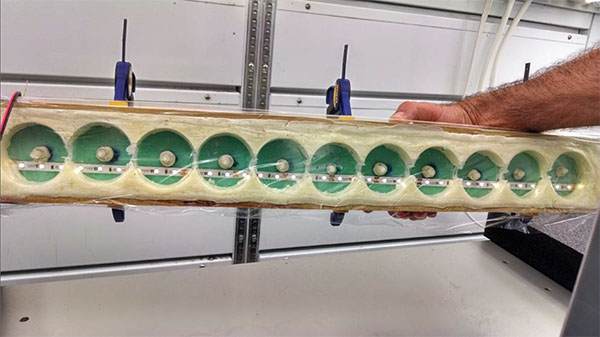

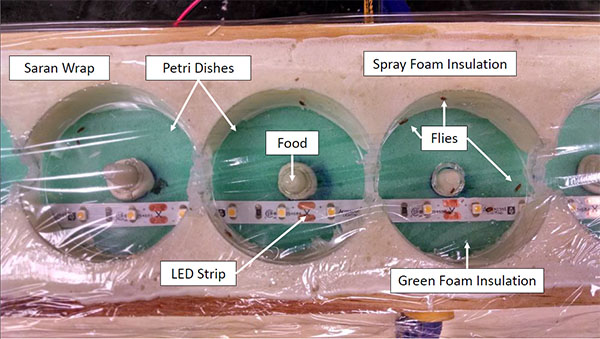

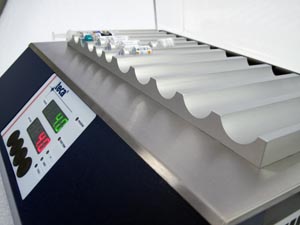

We received the following feedback from the customer: TEMPERATURE PREFERENCE TESTING: Creating Microclimates for Insect Subjects Using TECA’s Gradient Bar System, a biology department at a U.S. university created a temperature preference device for small insects. The insects were infected with various pathogens. The researchers wanted to create an environment where the insects chose a temperature benefitting pathogen replication/transmission and not host survival, thus determining whether pathogens alter their hosts’ temperature preferences.

Insulating their petri dishes and setting the entire gradient machine inside a larger incubator, the researchers created a microclimate and had excellent control over temperature fluctuations. TECA’s Gradient Bar System consists of two AHP-1200CPV Cold/Hot Plates (one at either end) and a TGB-5030 Gradient Bar. The temperature at each end of the gradient area can be programmed to a single set point or with a ramp/soak profile. Data logging software is included. Smaller systems can be created using AHP-301CPV Cold/Hot Plates. Custom gradient bar sizes are available. AGRICULTURAL RESEARCH USING TEMPERATURE GRADIENT: A department of the Canadian government uses two TECA Thermal Gradient Bar (TGB-5030) systems to conduct thermal behavior research on insects. In the photographs shown here, the customer used two AHP-1200CPV Cold/Hot plates plus one Large Gradient Plate (p/n TGB-5030) and created a gradient area spanning from 4 degrees C to 33 degrees C.

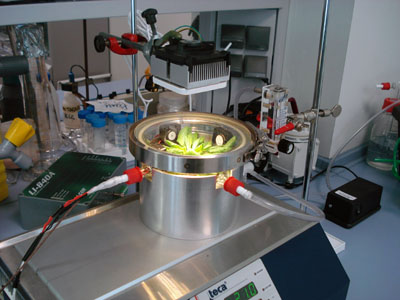

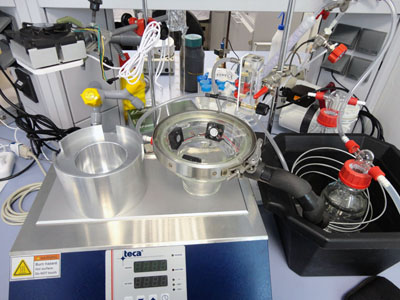

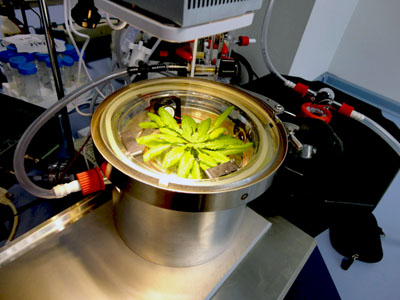

Two groups of insects were placed side-by-side on the gradient bar, in separate cages. This allowed the researchers to test two groups at the same time. The research has been submitted to be published in an academic journal. Please see the What’s New or the 2012 Innovations sections of this website for other published article citations. LABORATORY RESEARCH, MEASURING PLANT METABOLISM: A university-based agriculture research laboratory in Spain is measuring plant metabolism under various conditions. TECA Corporation's high-capacity version of the AHP-1200CPV (please refer to part number 9-35EB-1-0A0 on our product specification sheet) is used to cool the plant to 22C. Precise temperature control is important in this application as the plant's roots must not get too cold. There is a significant heat load to deal with as well: the plant is being illuminated with LED lights. Finally, thermal contact is an issue. The plant is inside a glass container, which is inside an aluminum block, which is placed on the AHP-1200CPV Cold Plate surface. Working closely with TECA engineers, the customer was successfully able to integrate the AHP-1200CPV Cold Plate into this unique experiment design and his sensitive thermal management needs were met.

The customer shared with us: TESTING PROPERTIES OF MATERIALS:

A 2mm-thick specimen was sandwiched between two laboratory-built hot plates. The hot temperatures were as high as 400C. The AHP-1200CPV cold plate cooled the researchers' load to 30C. Our customer reports that he was able to maintain the 30C temperature within +/- 2C. TEMPERATURE CYCLE:

A university research laboratory uses TECA’s AHP-1200CPV Cascade system to perform nucleation studies. The AHP-1200CPV Thermoelectric Cold/Hot Plate paired with a CCP-31 Cascade attachment creates a low-temperature cooling system. The customer is able to control the temperature of an aluminum dish, rapidly cycling between +20 C to -45 C. The Plexiglas box on top is to contain a dry nitrogen flow, which prevents condensation and frost from forming on the experiment stage. MEDICAL LABORATORY: Some researchers at Johns Hopkins have taken the AHP-1200CPV thermoelectric cold plate (Peltier cold plate) and are cooling protein crystallization in Teflon trays with a solution in them. They’ve used the remote sense feature by drilling a hole in Teflon tray and installing the sensor in there.

MEDICATION STORAGE: Keeping medication at optimal storage temperature is very important. A customized AHP-1200CPV thermoelectric cold plate (Peltier cooling plate) with plate that has grooves with various diameters to accomodate vials of different sizes and lengths was a perfect solution for the customer.

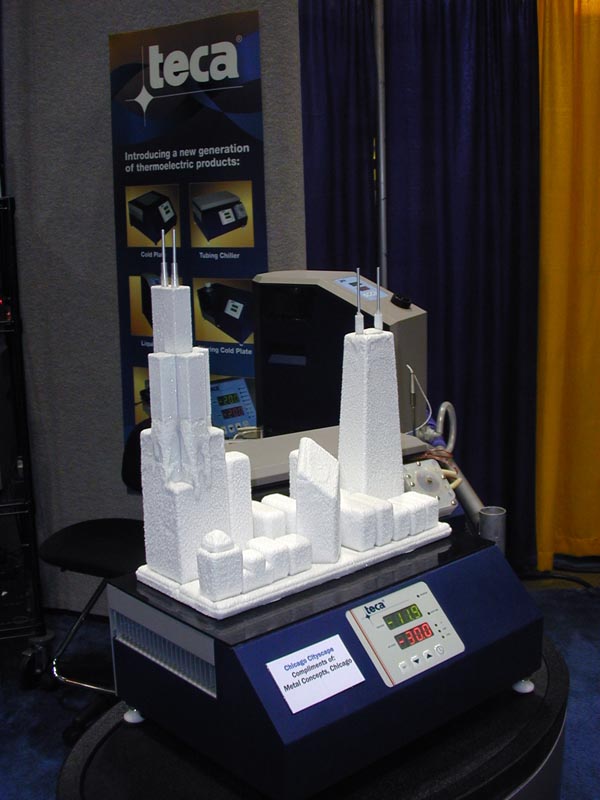

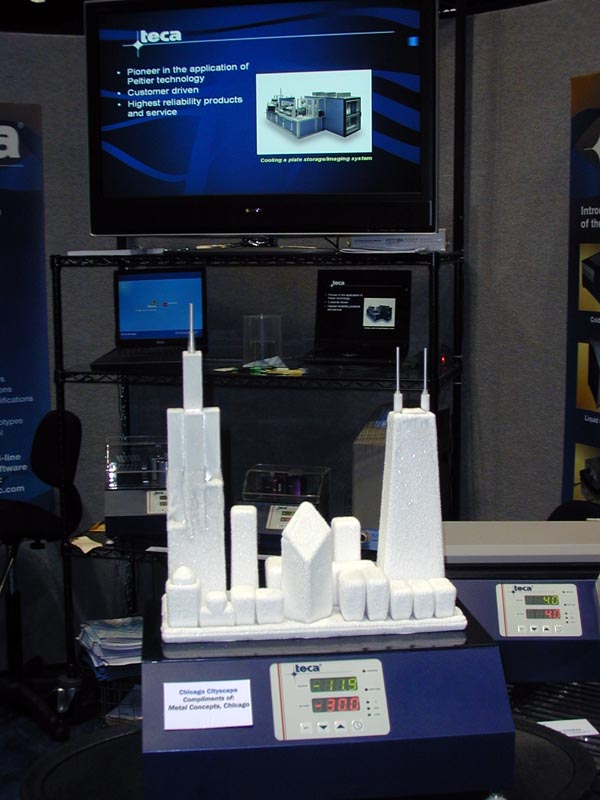

Another feature of this custom thermoelectric cooling unit (Peltier cold plate) is tamper proof temperature controller. Have you ever wondered what the Chicago Skyline looks like after a nasty Noreater blows in off the lake?

The creative machinists at Metal Concepts in Chicago constructed this cityscape to highlight the cooling capacity of our AHP-1200CPV product. The V stands for Versatile and given it’s used in so many industries I guess it’s not hard to see it cooling the city. Interested in cooling a city of your own? Send us some pictures or sketches and we’ll see what the artists at Metal Concepts can do for you. EQUIPMENT TESTING AND MAINTENANCE:

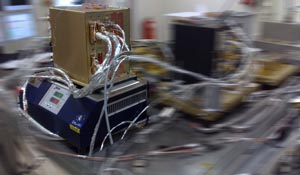

Three AHP-1200CPV Cold Plates are running continuously and in tandem at 17°C to monitor satellite equipment. The customer has added air deflectors of his own design. TECA offers standard air deflectors as well. The customer applies approximately 50 watts of heat to the cold plate. ISOTOPE RATIO MASS SPECTROMETRY LABORATORY:

USF Geology Stable Isotope Laboratory installed a second auto-sampler with a TECA AHP-1200CPV cold plate to keep samples at precisely controlled temperatures to prevent condensation and evaporation of the sample within the vials, and maintains the thermal stability required for isotope ratio mass spectrometry of water samples analyzed by equilibration method. QUALITY CONTROL: The AHP-1200CPV is used in a customer's Quality Control inspection process. The customer required a specific piece of equipment that would allow for bench top inspection of solution samples contained in small vials. Maintaining a 5C temperature throughout the QC inspection process was crucial. Ease of use and dependable control by TECA Model AHP-1200CPV Cold Plate has made the customer's process more efficient.

They manufacture navigation devices for land, road,

OPTICS:

A research and development team in Europe uses the TECA Model AHP-1200CPV Cold Plate with a TECA Model TC-1 Tube Chiller attached. Their process is proprietary but involves optical material and measurements. The TC-1 Tube Chiller is designed to heat or cool fluid without introducing contaminants to the fluid. The fluid flows through the flexible tubing (various tubing diameters are possible) within the plate surface. HEARING AID:

BROADCAST MICROWAVE SYSTEM: Customer uses TECA AHP-1200CPV cold plate for a very accurate temperature control of a transmitter.

The temperature of the unit under test is always the same, no matter what power it dissipates.

COSMOLOGICAL PHYSICS:

CASCADE COLD PLATE:

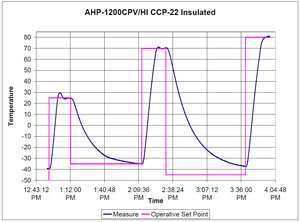

Here’s a step by step of an AHP-1200CAS/CCP-22 Cascade system our engineers were playing with. They took a purple EasySep magnetic nano particle vessel, set it on the cascade, insulated it and then cycled it up and down for kicks. The curve shows the results. Faster times can be achieved by thinning out the plates and building the cascade into the The CWB-01 cold well was first developed as an AHP-1200CPV custom accessory for the petrochemical industry. It replaced the need to maintain ice baths for the storage of chemicals. It has the advantage of good temperature control in either heating or cooling modes.

The temperature of the cold plate can be referenced to the fluid temperature or the remote sensibility feature of the CPV can be used to control based on the actual fluid temperatures. COOLING OF PURE FLUID FLOW:

The customer needed to cool a very low flow rate of a very pure fluid. Passing tubing through an ice bath did not provide close enough and consistent enough temperature control. However by using the AHP-1200CPV with tube chiller option and by determining the optimum set point a consistently cooled flow of the pure fluid was obtained. PHARMACEUTICAL LABORATORY: Keeping drugs cool on the bench A private biopharmaceutical company formulates drugs that are sensitive to temperature. TECA Model AHP-301CPV is their perfect benchtop cooling solution. The customer uses the AHP-301CPV Cold Plate in combination with the customer's own aluminum blocks to keep solutions at 0C during filtration and vial filling operations. The customer reports, “We have been very satisfied”.

This customer provided photo is a wonderful example of the versatility of TECA's line of Laboratory Cold/Hot Plates. The plate surfaces are appropriately sized to accept microtiter plates and other lab accessories. The temperature can be read from either the plate surface or anywhere a remote sensor can be placed, via the Remote Sensibility™ feature. LABORATORY EQUIPMENT: A research organization had a problem with overheating of their equipment in a chemical-vapor deposition reactor.

TECA’s AHP-301CPV Cold Plate cooled the equipment and improved the performance of the customer’s system. The customer was able to avoid system failures, which allowed the completion of a research project. COOLING ASPHALT SAMPLES:

An oil refinery runs tests on asphalt samples at different temperatures. TECA Model AHP-301CPV The gradient plate shown is not TECA’s. It’s from a University. They had been running a hot plate on one end and a liquid cooled LHP-300CP with the plate in the evaluation of temperature preference in insects.

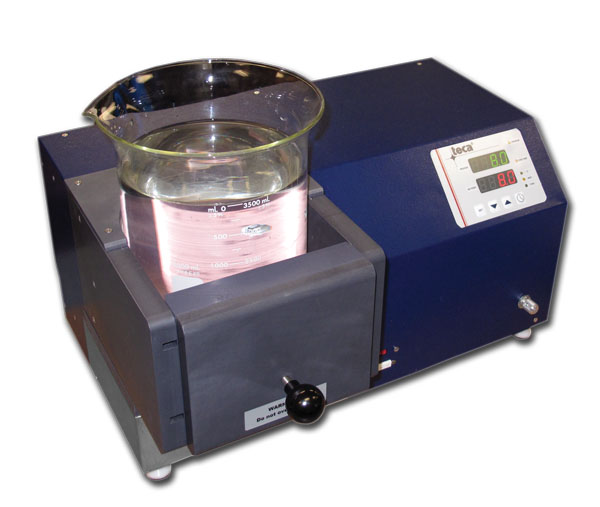

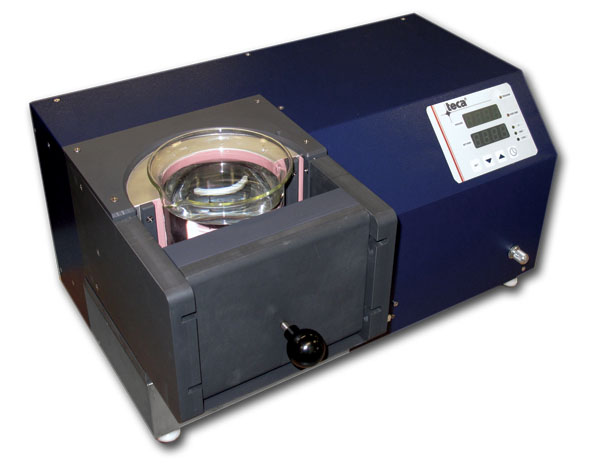

They needed better control and a wider temperature range and they wanted it on their existing plate. Many tests were run with the AHP-301CPV (shown) and the AHP-1200CPV to evaluate temperature uniformity and differential. More and more researchers are looking into the versatile CPV line of cold plates to improve their tests with the CPV line of products and accessories. Call us. Maybe we can help you too. AHP-800MSP Stirring Cold/Hot Plate: R & D LABORATORY:

An R&D laboratory needed to quickly cool beakers of high-concentration sucrose samples to 10C. The customer reports that using TECA's AHP-800MSP Magnetic Stirring Cold/Hot Plate system has been successful. The customer has different sizes of samples, which are accommodated by TECA's sleeve accessories. The customer uses 2L, 1.5L, 1L and 800mL sleeves at different times with the AHP-800MSP system. The sleeves are easy to switch in and out and add versatility to the system. In fact, unique to this product is the adjustable nature of many of its features: stir-bar speed, fan speed (for noise reduction), and temperature sensing (internal or external). ANODIZING ALUMINUM: A technological university in Asia chose TECA' s thermoelectric cooling Model AHP-800MSP Magnetic Stirring Cold/Hot Plate to anodize aluminum. The researcher's process required a temperature of 10C.

The AHP-800MSP's universal input voltage feature (100-240 VAC) allows it to be used anywhere, making it a perfect, off the shelf choice for our customer in Asia. He wrote to us: “It is quite good. Also the manual is quite clear and quite user-friendly. Thank you.” Unique to this product is the adjustable nature of many of its features: stir-bar speed, fan speed (for noise reduction), temperature sensing (internal or external) and more. The AHP-800MSP can even accept beakers of various size by adding optional sleeves. The solid-state thermoelectric construction is low-maintenance. There are no filters to change and no moving parts except for the fans. Our products use robust thermoelectric modules and boast a long service life. QUICK COOLING OF A LOAD FROM 100 C: A company specializing in hydrogen fuel cell technology required fast cooling of a fixture. The fixture is bonding multiple thin materials and can be heated up to 100C. The fixture needed to be cooled to the point where it could be handled by technicians—within a 5 minute time frame. Using two AHP-1200CP Cold Plates from TECA, the customer has created a system where a heat sink is cooled on one AHP-1200CP Cold Plate while a hot fixture is sandwiched between a second AHP-1200CP Cold Plate and a pre-cooled heat sink.

The customer reports being very happy with the TECA Cold Plates—the system is cooling in about 4 minutes! The AHP-1200CP Cold Plate is an economical, easy to use product when maximum cooling is required, without a temperature controller. 120VAC, 240VAC and 24 VDC versions are available. A SIMPLER WAY TO COOL MOUNTING WAX:

A product design engineer at a medical device company needed a way to cool wax blocks holding film. The wax is printed directly onto the customer’s aluminum tray. Before discovering TECA products, the customer was placing the aluminum tray in a refrigerator and mechanically removing the wax by scraping it off with a metal blade. TECA’s AHP-1200CP Cold Plate is a better solution. Please view the video provided by our customer to see how quickly and easily the wax is now removed (no more scraping!) The customer is happy to have found an affordable cold plate to dedicate to his cooling task. ELECTRONICS ENCLOSURE COOLING: Customer plans to use the TEC unit to regulate the temperature of some electronics in an outdoor enclosure. The electronics will be mounted to a cold plate where they can be cooled by direct contact with the TEC. The walls of the enclosure will be insulated to reduce thermal losses to the outside world. The hot side of the TEC will be in a separate, ventilated part of the enclosure to carry away waste heat. Customer will provide longitudinal air flow along the heat sink, so the built-in fan will not be necessary. Originally considered using a solid-state air conditioner to cool the entire enclosure, but now prefers the direct-contact method for lower cooling requirements and smaller size.

The active load that needs to be cooled is about 50W. It will consist of a number of RF components (amps, sources, etc) mounted to a common cold plate. Several passive components will also be mounted to the plate. The whole temperature-controlled assembly will be insulated by an inch or so of foam or something similar. The ambient temperature range is roughly 0 to 100 degrees F at the extremes. FLUID DISPENSING: A leading manufacturer of fluid dispensing systems uses one of our Thermoelectric Cold Plate and Temperature Controller for controlling the fluid temperature of adhesives, sealants, lubricants and other materials in meter, mix and dispensing systems.

Unlike other larger, higher cost and less accurate heating and cooling devices, which use heater cartridges, refrigerant or water to heat and cool, these thermoelectric-effect temperature controllers use the Peltier-Seebeck effect to directly convert electrical voltage to thermal differentials. This effect, which is reversible, either heats or cools fluid materials with precision to the temperature set point. The compact Peltier thermoelectric device, temperature sensor and the temperature control is mounted to a manifold where the fluid passes through to be precisely heated, maintained or cooled. BEVERAGE COOLING: Here’s an application that TECA’s engineering team was particularly excited about. Not because of the economics or the potential new business. Frankly we didn’t think the market was there. But as soon as they found out that a ½ barrel of beer would be needed for testing they were all over it. While none was ever sold, good lessons regarding contact methods and material stratification were learned. To see the result of the test click here.

CHEMICAL WASTE TRANSPORT: Here’s an application that our engineering crew would love to put into greater use if they could figure out where and how. A specialty gas company called. They wanted to transfer toxic and corrosive liquids from big to small containers for lab use. The process had been taking several minutes with too much wasted product. They knew because of the conditions a natural head pressure in the big container that they could use a cold plate to cool at the receiving vessel (1.5 dia x 12" bottle) to create a driving force which moves the fluid. We didn’t go into the physics of this, we trusted what the customer said and worked with them. When they tried an AHP-1200CP it was fantastic. It turned 4 minutes and a lot of waste into no waste and 40 seconds. COOLING WAFER: The adjustable feet on this AHP-1200CP Peltier cooling plate (thermoelectric cooling plate) made life easier on the factory floor.

Customer wafers needed cooling at the end of processing and the feet brought the cold plate up to the perfect height to match the production mechanisms. Just a little option that TECA is ready to provide to make the products we build work for you. MANUFACTURING:

Here’s another example of an AHP-1200CP thermoelectric cooler plate (Peltier cooler plate) used in a manufacturing station. The adjustable feet provide vertical flexibility in lining up the cold plate with the workstation. Parts slide easily from the hot plate to the work surface to the cold plate. THEME PARK EXHIBIT: A company specializing in 3-D designs for museums, theme parks, and other attractions needed to build an "icy throne" for a museum exhibit and keep it dry at the same time.

MEDICAL LABORATORY: Department of histology in a major hospital needed a peltier cold plate to freeze tissue samples for examination.

The Histology Division of the Department of Pathology places tissue samples from biopsies into a small block and fills it with wax. Several of these samples are then placed on one of the AHP-1200CP thermoelectric cold plates (Peltier cold plates) to "pull the heat" out of the wax so it gets really hard. The near-frozen samples are then shaved down to the desired section (slice) using a Microtome (in picture). The thin sections are then placed in the water bath to warm up the remaining wax in order to remove it and then place the section on a slide for examination. INDUSTRIAL MATERIAL:

In this example of an AHP-1200CP application a box surrounds the cold plate area. Materials are set directly upon the cold plate and the lid is closed. The material is cooled and temperature controlled without the large air cooling refrigerator. 3D PRINTING PROCESS: The AHP-301CP Cold Plate has simplified the customer’s process by replacing a messy hot wax system.

A customer heard about TECA’s Thermoelectric Cold Plates through word-of-mouth and placed an order within the week. The AHP-301CP Cold Plate is used in the customer’s 3D printing process. Parts are printed on an aluminum plate which is then set on the AHP-301CP Cold Plate. As the AHP-301CP Cold Plate cools the aluminum plate, the 3D prints just pop right off of the aluminum plate. The customer is pleased with the performance, ease of use and low purchase price of this basic model. COOLING LED CHIPS:

The customer was looking for a cooling solution for LED chips. With a heat load as high as 45 watts at times,

PERFORMANCE TESTING: Customer needed to test low-temperature performance of inertial measuring devices.

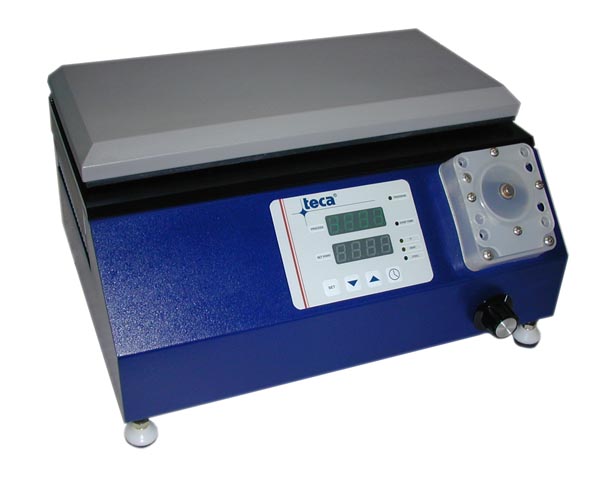

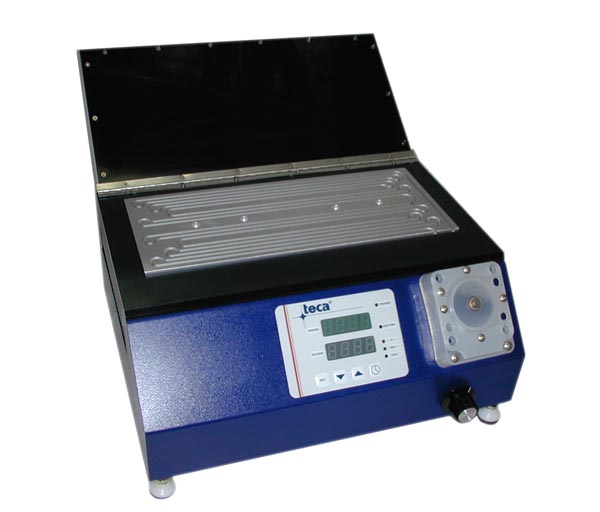

The custom thermoelectric cold plate cascaded (Peltier cascade) was built up from a standard Model AHP301CP cold plate. The finished test fixture was able to function with a maximum rotation rate of 1700 degrees per second and 50g acceleration. The rotation is evident in the photo. By using a standard product as the basis for the cooling system, higher costs associated with a custom solution were avoided. COOLING FLUID FLOW: Chilling liquids being circulated by a peristaltic pump under ultra-clean conditions. When handling and processing various fluids in laboratory and electronic environments cleanliness is a must. Peristaltic pumps have been developed for the purpose of creating a fluid flow without contacting the fluid itself.

TECA developed a liquid chiller to cool fluids, while satisfying the same cleanliness requirements. The solution, based on our successful cold plate product line, has proven to be versatile and effective. Pictured here is the first prototype of a multiple-pass tube cooler for use with a peristaltic pump. Applications range from laboratory to medical to industrial. COOLING FLUID FLOW:

A customer needed to cool high pressure flow of fluid in a single pass. Using expanded Aluminum foam and attaching it to the surface of AHP-301CP thermoelectric cold plate (peltier cold plate) provided a way to maximize the thermal contact surface and eliminated the need to complex fluid path and larger cold plate. A potential customer expressed interest in a cooling/heating system for an aerosol flow tube envisioning a 1 inch OD, 0.875 inch ID stainless steel flow tube mounted inside a 2-2.5 inch ID pipe (likely also stainless steel and insulated on the outside) capable of controlling the tube at temperatures ranging from roughly 5 degrees C to 40 degrees at an ambient temperature of 25-30 degrees Celsius. We are measuring the change in particulates in the air due to the temp change. Standard liquid chillers were first offered along with technical design assistance. The requirements led to direct contact cooling as being a good solution. Standard cold plate products and controllers were offered which led to this request for a custom package. “We would like to have the flow tube sandwiched between the cold plates with the temperature controller and power supplies attached in a similar manner so that we only need attach the temperature controller (the TC-3400 appears as if it will work) to a computer so that we can change the set points remotely. Is any of this even possible or am I dreaming in Technicolor?” We advised him that the best dreams were in color. Preliminary design work was done and a quote prepared. Shortly thereafter an order was received; design documents were completed and sent to production. Less than 3 months after the initial contact the product was shipped. Several months later a follow up was made with this response. “Things are doing really well. It does exactly what we wanted it to do, and is much more efficient and better than we hoped for. We're very happy!

CANADIAN FOG BOX: Below are few pictures of the “Canadian Fog Box” that our customer constructed using TECA's AHP-300CP cold plates, power supply, and TC-3400 PID controllers.

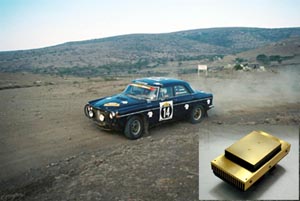

The interior of the box is covered with mirror finished aluminum to reflect the ultraviolet rays from the bulb in the bottom. The top is normally closed as well. The insulated glass unit is then inspected for any condensation inside where the cold plates contacted the glass. Any other ‘fog boxes’ use water flow cold plates to maintain temperatures. TITER PLATE COOLING: The WWW brings many to TECA’s door. These particular customer requirements were filled by an AHP-300CP Peltier cold plate. He needed to control the temperature of a 96 well titer plate in a new product design. But he needed just a few things the standard unit didn’t provide and he didn’t need some that it did provide. He wanted a 24 VDC heat cool system with continuous fan operation and a custom tap pattern on the cold plate. In short order the TECA sales team assigned a preliminary part number, passed the requirements through to engineering and together the first units were modified and shipped. This gave the customer plenty of time to work with the solid state cold plates and refine his requirements into the custom design he uses today. MOTOR SPORT: A rally car racing team had a need to chill drinking water inside their moving vehicles, while they raced through very hot desert conditions.

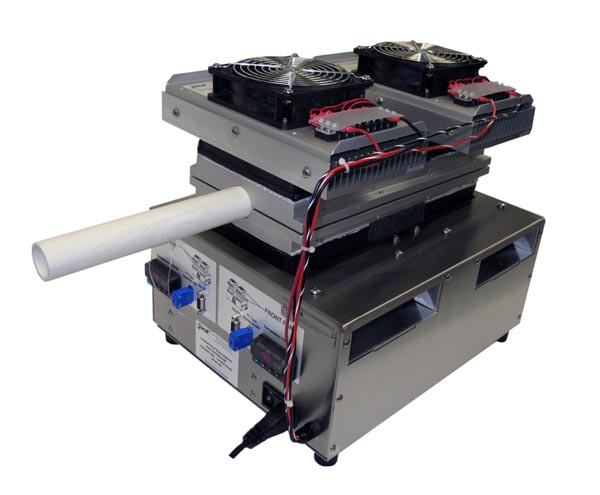

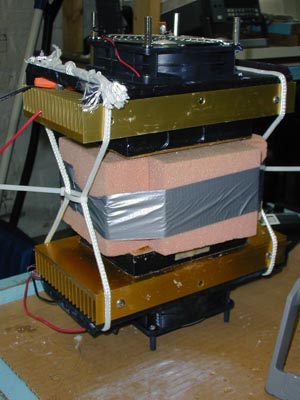

A solid state cold plate based on TECA model AHP-300CP. The AHP-300CP thermoelectric cold plate (Peltier cold plate), which draws power directly from the car battery, was the solution to maintain the temperature of the water at an acceptable level. With a ready supply of chilled water, the racing team could drive at peak performance. LOW TEMPERATURE CASCADE: A cascade sandwich is what we called this that day. The customer needed a fairly large mass cycle between two extremes. The mass and size of the load were limiting factors.

The pictures and assembly look crude, and it was, but they were also effective.

A company that offers a broad range of door and window components and related building products with proven product lines and a multi-state collection of modern manufacturing facilities uses the AHP-150CP in a Canadian Fog Box, for testing double pane windows for condensation.

OEM LABORATORY EQUIPMENT: As a component in an OEM laboratory chamber, the AHP-150CP condenses out moisture to control humidity. COLD PLATE / CONTROLLER SYSTEM:

If you’re putting the pieces together rather than buy a complete system it might end up something like this. Pictures are an AHP-150CP with no insulation or sealant, a TC-4300 with

Our customer asked for a quote on delivery and price for the LHP-800CPHC. He then asked if we had a liquid cooled version of the AHP-1200CPHC (15" x 7.3" plate)?

The product had been in the works but on the back burner. This customers request pulled it to the front. We offered an LHP1200CP. It would be liquid cooled with 15 x 7.3 cold plate requiring 24 VDC input.

The customer later set it up with a water pump and a radiator/fan arrangement to provide a recirculation cooling water path rather than connecting to the tap and sending it down the drain. LIQUID CHILLER COLD PLATE CASCADE:

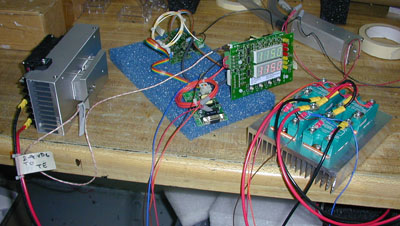

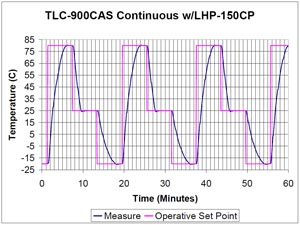

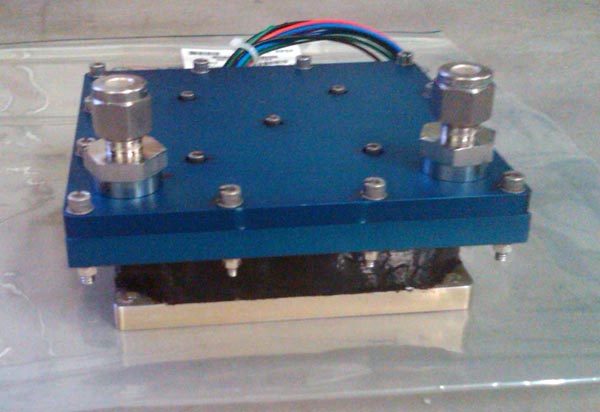

Here are pictures of the TLC-900 thermoelectric liquid chiller with LHP-150CP Peltier liquid cooled cold plate set up run in the lab. The “load” is a plate with 10 power resistors mounted to the top and a series of thermocouples measuring the surface of the LHP-150CP’s thermoelectric cold plate. During the test the power to the resistors is increased in steps with enough time in between for the temperatures to stabilize. Plotting the data resulted in performance curves. The test was made with the load insulated and with the load simply covered. Later on we used a TLC-900CAS, a version of the TLC-900 made specifically for running and controlling secondary cold plates like the LHP-150CP and ran some step, ramp and soak profiles. VACUUM CHAMBER:

Some engineers at Lucent wanted to cool devices inside a vacuum chamber and they didn’t want to reinvent the wheel. TECA’s been making devices like that for decades. They had a load of 10 to 20 watts generated and wanted -40C with about 15 to 20 C water available. A Custom LHP-800CP/300CP cascade, controller and power supply were supplied for a reasonable cost in a reasonable time frame. A Medial Doctor was interested in a Peltier based “Cold Probe” to anesthetize the skin prior to treatment. He wanted an instrument that ran on batteries based around the Otoscope or the Ophthalmoscope with interchangeable heads. It was a medical application, a prototype and a long shot one at that. .He came to TECA with some rather limiting criteria to do a big job considering the load human skin presents. We did our best and gave the good Doctor his cold probe.

We designed it, packaged it, powered it and built it. But not many folks really needed it. Not a complete market success but a technical one. Above is a picture of it. Cryogenic fluid is extremely sensitive to temperature and pressure changes within an experimental environment.

A custom-modified version of TECA’s LHP-300CPHC Liquid-Cooled Cold Plate is installed as part of a system which allows the customer to closely monitor and control temperature. The long life expectancy and low maintenance requirements of the LHP-300CPHC offer reliability and convenience to the customer’s long-term research experiment. INDUSTRIAL ADHESIVE COOLING:

These folks needed to cool a thick fluid that ends up being gaskets when robotically dispensed. A custom version of our AHP-1200CP fit the bill perfectly. Now the product is dispensed consistently because of the temperature control provided by thermoelectrics.

CUSTOM COLD PLATE: The people at MIT who wanted the plain black anodized cold plate never did tell us what it was for. We think maybe they are using it to calibrate or adjust infra red temperature detectors. We could be wrong. They might have thought it just looked cool. For whatever reason, they told us what they wanted and we did our best to meet their requirement.

STIRRING COLD PLATE: A Peltier stirring cold plate was needed to cool liquid inside a standard 1000 ml plastic tank and maintain the class 100 clean room rating. Custom designed thermoelectric stirring cold plate with integral variable stir speed control, temperature control, alarm and remote sense capability.

TECA is glad to participate in custom and OEM product development. Over the years we have come up with some pretty innovative and novel products for our customers. This product was developed from scratch for a customer which was a start-up company in the field of pharmaceutical development. This TECA cold plate apparatus is designed and built for use in a clean room facility. The controls are ergonomic. The user can easily adjust controls for stir speed, timing and temperature even while wearing clean room garb and sterile gloves. Unfortunately for the start up company, their funding was pulled and they are not around any more. The stirring cold plate was taken over as a proprietary product by TECA. AVIONICS: A branch of the US military had an overheating problem with a high-tech radio inside the wing of a fighter aircraft. TECA developed a custom, high-performance cold plate that withstand the shock, vibration, and G forces created by one of the most technically advanced aircraft. In order to assure maximum strength with minimum weight, TECA's Advanced Machining Center machines the finned heat sinks for each cooler from a single blocks of material. PORTABLE MEDICINE COOLER: Portable cooler needed for carrying emergency intravenous solutions, all components must be enclosed within the case. TECA designed a custom thermoelectric (peltier) based cold plate built into a Pelican™ Box.

TECA is developing this product for a new customer. We have taken a standard Pelican™ Box and configured a battery powered thermoelectric cooling system which is installed totally inside. This cooled box is for the purpose of transporting up to 4 liters of emergency intravenous solutions safely. There are fitted compartments inside as well for transporting other necessary items for patient care. Since nothing is exposed or protruding from the box, our customer has ended up with a good looking and very rugged, functional thermoelectric product. ENVIRONMENTAL CONTROL: A municipal waste plant had an emergency requirement for a water drop device (to condense moisture for analysis) to be installed in a smokestack.

In this time critical application TECA responded with a custom designed variation of the AHP-150CP thermoelectric cold plate, to be mounted high up in the stack. Working with the customer TECA was able to design and deliver the product in less than two weeks, more than meeting the customer’s timetable. BEVERAGE COOLER: The application was to keep concentrated beverage container located next to a hot water tank cool in a high volume OEM application. TECA has always had the flexibility and resources to manufacture custom OEM thermoelectric cooler (peltier coolers) assemblies intended for use as part of a customer machine, apparatus, or system.

This OEM assembly is made by TECA in production runs in the thousands. It is not ours, so to protect the privacy and identity of our customers we can’t give too many details here. This assembly is part of a beverage service product which is shipped worldwide by a well known consumer products company. TECA furnishes the cooling "engine" which refrigerates the beverage product to be dispensed, and the OEM builds finished machinery in their own plants. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Things you need to know to start sizing a liquid chiller: Temperatures: The ambient temperature is the air temperature around the liquid chiller. The desired temperature is the fluid temperature at the outlet or at a location on the item being cooled. The difference between the two is the design temperature differential (delta T). Typically the fluid temperature has to be a little cooler than the item being cooled. Make sure to include any gradients from the fluid to the test item. Also include any increase or decrease in the fluid due to the hoses. While these differences are typically small, large hose lengths and poor thermal coupling between the fluid and the device under test can increase them. Heat Loads Active and Ambient: We define an active load as any source of heat. Waste electric heat or exothermic reactions are examples. Loads can also be related to the specific heat of a sample when cycle times are important. Ambient loads are caused by the temperature differential between the ambient and the fluid in the hoses Performance Curves: The total load and temperature differential (delta T) can be applied to the performance curves of the liquid chillers to determine if the capacity is sufficient. Complete details on this process can be found on Page 10. Fluid flow requirements: What flow rate is required? What is the pressure drop at that flow rate? Will the hoses significantly affect the pressure drop? Graphs of the flow vs. pressure drop are available for each liquid chiller. Things you should consider when selecting a liquid chiller: Purpose: What is the real need for cooling: maintaining electronics temperatures, precision temperature control, maintaining sample temperatures, cooling a process, temperature cycling? Is this a laboratory or industrial setting? Do I need portability? Is this an OEM application where the chiller must be packaged into your product? Answering these questions will help in selecting the correct liquid chiller for your application. Temperature Control: Some applications simply require cooling with no fancy temperature controls. The TLC-1200 and the TLC Cubed products often best fit these needs. When better control and more control features are needed the TLC-700 and TLC-900 are used. The TLC-900 has a remote sensor feature standard allowing you to control the temperature at a point downstream or on the device under test. Each application should be evaluated independently to assure safe and proper control. Type of Fluid: TECA recommends using distilled water. Regular tap water can be used also although “hard” water may cause mineral deposits to build up. For those applications which may go below 0 C a mixture of 25% ethylene glycol and distilled water is recommended. Algaecides are also commonly used additives. Fluids other than water must be evaluated on a case by case basis. Cooling Medium: All standard TECA liquid chillers are air cooled products. Environment: In general our standard liquid chillers can handle factory, lab and office environments. No standard unit is made for outdoor or wash-down environments. Typical locations are bench top, under bench and rack mount. Custom versions have been made for many environments. Power Input: Liquid chillers requiring universal input 100-240 VAC, 120 VAC, 240 VAC, 120/240 VAC and 24 VDC are available. Connections: Most liquid chillers have connectors, hoses, clamps and hose insulation included as part of their standard package. What sort of connection is required at the device under test? NPT tap? Hose barb? What sizes? It’s best to answer these questions up front to avoid problems down the road CHEMICAL VAPOR DISTRIBUTION SYSTEM: An OEM customer integrates TECA's Model TLC-900 Liquid Chiller into a bubbler system designed to distribute chemical vapor via a carrier gas. The bubbler vessel is filled with the liquid chemical. The carrier gas is bubbled through the vessel and TECA's TLC-900 Liquid Chiller maintains the chemical at a temperature determined by the end user, to maximize process control. The customer chose TECA's TLC-900 Liquid Chiller over others because of its heating and cooling capability and the versatility of its universal input voltage (100-240 VAC). The customer's system is sold worldwide and quality and reliability are key. The customer shared with us: TESTING PROPERTIES OF MATERIALS:

A materials scientist at a state university uses TECA's TLC-900 Liquid Chiller to cool transducers for an elastic modulus apparatus. The apparatus measures the elastic modulus as function of temperature. The elastic modulus is a material property.

t defines the stiffness of material. It varies with temperature and is used in design. The customer uses the TLC-900 Liquid Chiller to cool a plate, which then cools from 400C to between 30C and 50C. SEMICONDUCTORS: A research oriented organization uses TECA's TLC-900 recirculating liquid chiller to control the temperature of a semiconductors test stage where proximity of TEC would produce electromagnetic noise hard to screen.

CHILLER WITH 200' HOSE: A customer wanted a TLC-1400 thermoelectric liquid chiller (Peltier chiller) to maintain a 400 watt load under normal conditions except for one thing, the hose needed to be over 200’ long. Would it pump? How much of an effect would it have on the cooling capacity?

We could have run the numbers and come up with an estimate. It was really easier to just hook up some hose and a constant load plate, roll it into the environmental chamber and see what it did. It did more than it was supposed to. The customers safely bought it knowing it would do what he needed. COSMETIC TREATMENT: Photofacial treatments using intense pulsed light are said to remove spider veins and age spots, but are uncomfortable for the patient.

AIRBORNE THERMOELECTRIC LIQUID CHILLER:

CHILLING PROCESS INK: Here’s the way they’re all supposed to work:

MEDICAL: Customer needed a compact thermoelectric cooling system to cool flow of fluid through removable membrane liquid jacket for mobile medical application.

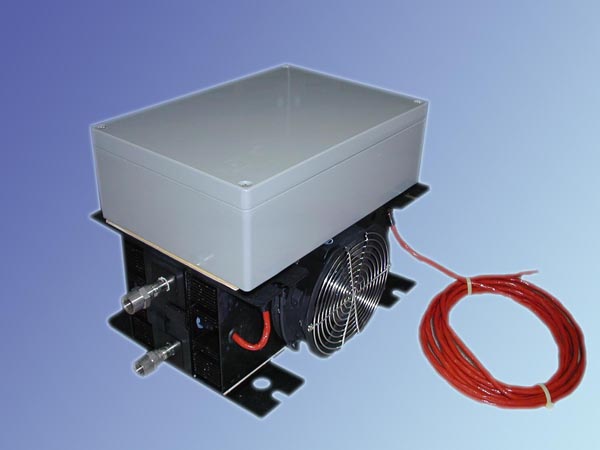

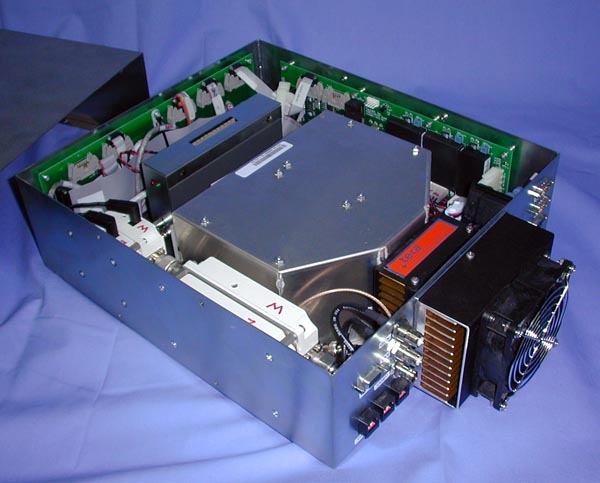

TECA’s sales and engineering team worked with the customer and developed the product you see in the pictures above for the exclusive use of our customer. The application is medical and will be protected by patent. Thermoelectric cooling will be employed for effective cooling of the brain for emergency treatment of stroke victims. MILITARY: The United State Navy needed a liquid chiller to circulate coolant and also meet strict military requirements.

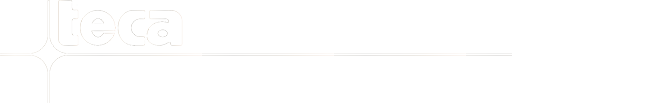

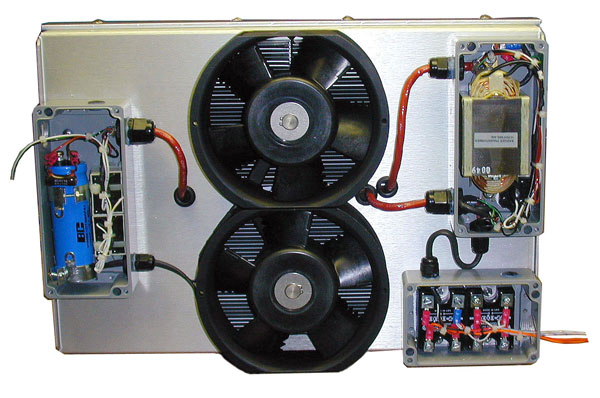

Here’s another custom military application by TECA. This is a liquid chiller for circulating chilled coolant as part of a tracking system on a NAVY ship. Note that the chilled liquid circuit is effectively “sandwiched“ between two heat sinks with rugged Mil 901 fans. Wiring and electrics are housed in a NEMA4X enclosure with an O-ring gasket seal. This unit is rated for shipboard use in salt-spray, shock and vibration. AEROSPACE MANUFACTURING: To meet a customer requirement TECA sales and engineering team modified a standard model chiller to meet a highly specialized demand of the application, including liquid cooling, 24 VDC input and wall mounting.

ANODIZING ALUMINUM: A technological university in Asia chose TECA' s thermoelectric cooling Model AHP-800MSP Magnetic Stirring Cold/Hot Plate to anodize aluminum. The researcher's process required a temperature of 10C.

The AHP-800MSP's universal input voltage feature (100-240 VAC) allows it to be used anywhere, making it a perfect, off the shelf choice for our customer in Asia. He wrote to us: “It is quite good. Also the manual is quite clear and quite user-friendly. Thank you.” Unique to this product is the adjustable nature of many of its features: stir-bar speed, fan speed (for noise reduction), temperature sensing (internal or external) and more. The AHP-800MSP can even accept beakers of various size by adding optional sleeves. The solid-state thermoelectric construction is low-maintenance. There are no filters to change and no moving parts except for the fans. Our products use robust thermoelectric modules and boast a long service life. LABORATORY: To chill liquids being circulated by a peristaltic pump under ultra-clean conditions without introducing contaminations is of outmost importance in laboratory applications. When handling and processing various fluids in laboratory and electronic environments cleanliness is a must. Peristaltic pumps have been developed for the purpose of creating a fluid flow without contacting the fluid itself.

TECA developed a liquid chiller to cool fluids, while satisfying the same cleanliness requirements. The solution, based on our successful cold plate product line, has proven to be versatile and effective. Pictured here is the first prototype of a multiple-pass tube cooler for use with a peristaltic pump. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Catalog | Sizing Software | Manuals | Applications | Site Map | Privacy Policy | Testimonials | Contact © 2014 ThermoElectric Cooling America Corporation. All Rights Reserved. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

To keep sensitive electronics used in truck processing terminals in safe and operable temperature range a system integrator company uses TECA

To keep sensitive electronics used in truck processing terminals in safe and operable temperature range a system integrator company uses TECA  overhead cranes. On top of all that the only power they had was a widely varying 250 VDC. Which we found out later had some very nasty spikes which caused everyone a few headaches. But the headaches were cured and the customized

overhead cranes. On top of all that the only power they had was a widely varying 250 VDC. Which we found out later had some very nasty spikes which caused everyone a few headaches. But the headaches were cured and the customized

TECA Model

TECA Model  A “quick quote” for two thermoelectric air conditioners came into our sales team. It was responded to and followed up. The application was reviewed, a quote was made and an order placed. Only after did we learn that the hard requirements they were looking for were:1) Dual adjustable temperature control (heat and cool) 2) 28 VDC operation and 3) Military environment. Fortunately the selections within TECA’s enclosure air conditioner family are large. The military Contractor borrowed a unit from TECA’s loaner stock and based on that success, placed an order. It was then that we found a problem. It seems that the application was to cool some sensitive electronics out on a 200 meter DC input which caused droop in the input which in turn caused a ringing in the circuits. The new digital monitors being used were susceptible while the older tube monitors had no issue. Working with the customer it was determined that by changing the controller to a ruggedized PWM controller all problems were solved.

A “quick quote” for two thermoelectric air conditioners came into our sales team. It was responded to and followed up. The application was reviewed, a quote was made and an order placed. Only after did we learn that the hard requirements they were looking for were:1) Dual adjustable temperature control (heat and cool) 2) 28 VDC operation and 3) Military environment. Fortunately the selections within TECA’s enclosure air conditioner family are large. The military Contractor borrowed a unit from TECA’s loaner stock and based on that success, placed an order. It was then that we found a problem. It seems that the application was to cool some sensitive electronics out on a 200 meter DC input which caused droop in the input which in turn caused a ringing in the circuits. The new digital monitors being used were susceptible while the older tube monitors had no issue. Working with the customer it was determined that by changing the controller to a ruggedized PWM controller all problems were solved.

Keeping sensitive electronic instruments and equipments at optimum operating temperature range often is one of the most important issues in designing an enclosure system housing the instruments. A manufacturer of first response vehicles was able to maintain it’s sensitive electronics in safe operating temperature range using a custom peltier cooling system designed by TECA Corporation.

Keeping sensitive electronic instruments and equipments at optimum operating temperature range often is one of the most important issues in designing an enclosure system housing the instruments. A manufacturer of first response vehicles was able to maintain it’s sensitive electronics in safe operating temperature range using a custom peltier cooling system designed by TECA Corporation.

Evaluating the condition of pipes in nuclear power plants can be time consuming and costly. Automated and remote guided methods are available. Much of the electronics for the job must be rugged and durable, capable of handling many environmental conditions.

Evaluating the condition of pipes in nuclear power plants can be time consuming and costly. Automated and remote guided methods are available. Much of the electronics for the job must be rugged and durable, capable of handling many environmental conditions.

.jpg)

.jpg)