|

||||||

|

||||||

Thermoelectric Cold Plate Applications |

||||||

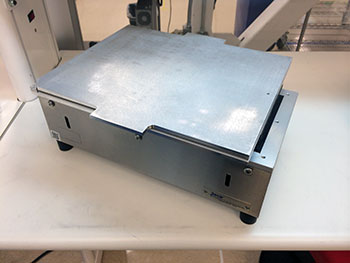

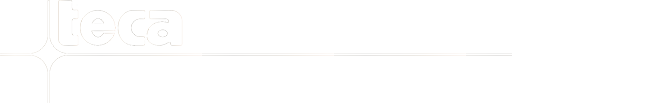

ELECTRONIC TEST STATION: An aerospace contractor was interested in a large cold plate for the testing of electronic components. We first offered them the AHP-1200CPV but they responded that the AHP-1200DCP was more the size they wanted. Could we change it to a single plate? Well we couldn’t change the plate size but we could add an accessory plate which was larger. And we could build the unit with one controller including all of the standard options.

Now they are using the 12” x 18” custom accessory plate and a special AHP-1200DCP to test electronic amplifiers by ramping the temperature up and down between +10 to +70. A custom solution at very nearly standard product price to fill a not so unusual need. |

||||||

COOLING 64 DEGREES BELOW THE AMBIENT: A medical device manufacturer uses a TECA Low-Temperature Cascade System in his design process. The Cascade System consists of a TECA Cold Plate and Cascade attachment. The system offers direct contact cooling to the customer's load. In this example, the customer was able to cool his load of Isopropyl Alcohol solution from +25C to -25C in about 35 minutes.

We received the following feedback from the customer: |

||||||

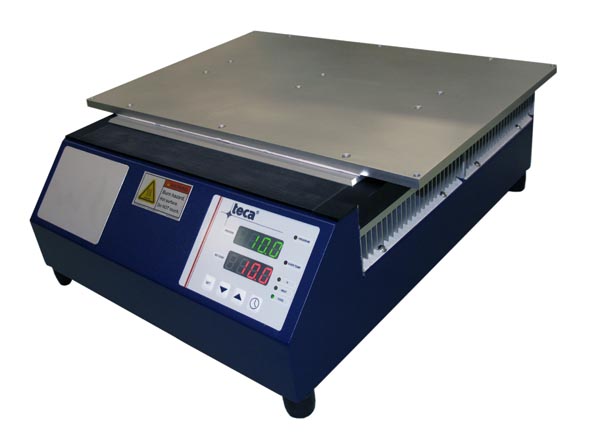

EQUIPMENT TESTING AND MAINTENANCE:

Three AHP-1200CPV Cold Plates are running continuously and in tandem at 17°C to monitor satellite equipment. The customer has added air deflectors of his own design. TECA offers standard air deflectors as well. The customer applies approximately 50 watts of heat to the cold plate. |

||||||

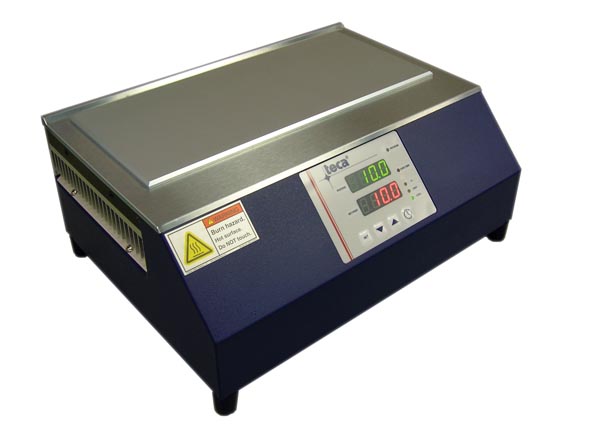

QUALITY CONTROL: The AHP-1200CPV is used in a customer's Quality Control inspection process. The customer required a specific piece of equipment that would allow for bench top inspection of solution samples contained in small vials. Maintaining a 5C temperature throughout the QC inspection process was crucial. Ease of use and dependable control by TECA Model AHP-1200CPV Cold Plate has made the customer's process more efficient.

| ||||||

|

They manufacture navigation devices for land, road, |

||||||

HEARING AID:

|

||||||

FIBER OPTICS: The customer makes fiber optics and related components and subsystems, they use an AHP-1200CPV cold plate for testing components. They are using it to run temperature test on them, they set the temperature, and it goes to temperature and sits there, heating or cooling. “It works well”.

|

||||||

BROADCAST MICROWAVE SYSTEM: Customer uses TECA AHP-1200CPV cold plate for a very accurate temperature control of a transmitter.

The temperature of the unit under test is always the same, no matter what power it dissipates.

|

||||||

HIGH SPEED CRYSTAL OSCILLATORS:

The customer makes high performance crystal oscillators and atomic clocks for satellites and laboratories and they needed something for temperature control and stabilization. They found TECA and the AHP-301CPV, tried one and say it is “working fantastic”. Well enough to order more for production, quality and engineering tests. |

||||||

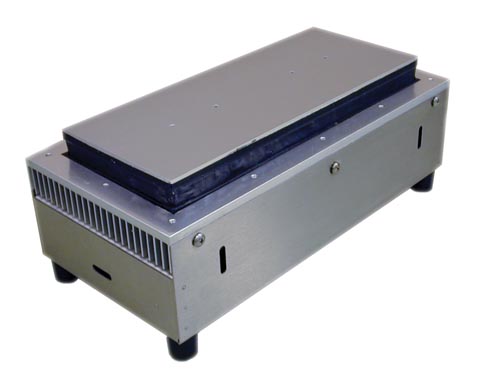

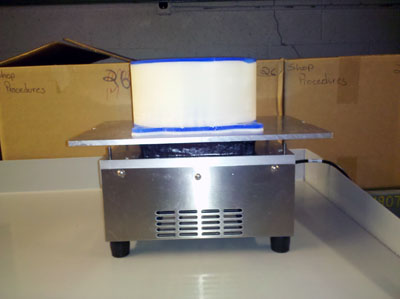

QUICK COOLING OF A LOAD FROM 100 C: A company specializing in hydrogen fuel cell technology required fast cooling of a fixture. The fixture is bonding multiple thin materials and can be heated up to 100C. The fixture needed to be cooled to the point where it could be handled by technicians—within a 5 minute time frame. Using two AHP-1200CP Cold Plates from TECA, the customer has created a system where a heat sink is cooled on one AHP-1200CP Cold Plate while a hot fixture is sandwiched between a second AHP-1200CP Cold Plate and a pre-cooled heat sink.

The customer reports being very happy with the TECA Cold Plates—the system is cooling in about 4 minutes! The AHP-1200CP Cold Plate is an economical, easy to use product when maximum cooling is required, without a temperature controller. 120VAC, 240VAC and 24 VDC versions are available. |

||||||

FLUID DISPENSING: A leading manufacturer of fluid dispensing systems uses one of our Thermoelectric Cold Plate and Temperature Controller for controlling the fluid temperature of adhesives, sealants, lubricants and other materials in meter, mix and dispensing systems.

Unlike other larger, higher cost and less accurate heating and cooling devices, which use heater cartridges, refrigerant or water to heat and cool, these thermoelectric-effect temperature controllers use the Peltier-Seebeck effect to directly convert electrical voltage to thermal differentials. This effect, which is reversible, either heats or cools fluid materials with precision to the temperature set point. The compact Peltier thermoelectric device, temperature sensor and the temperature control is mounted to a manifold where the fluid passes through to be precisely heated, maintained or cooled. |

||||||

CHEMICAL WASTE TRANSPORT: Here’s an application that our engineering crew would love to put into greater use if they could figure out where and how. A specialty gas company called. They wanted to transfer toxic and corrosive liquids from big to small containers for lab use. The process had been taking several minutes with too much wasted product. They knew because of the conditions a natural head pressure in the big container that they could use a cold plate to cool at the receiving vessel (1.5 dia x 12" bottle) to create a driving force which moves the fluid. We didn’t go into the physics of this, we trusted what the customer said and worked with them. When they tried an AHP-1200CP it was fantastic. It turned 4 minutes and a lot of waste into no waste and 40 seconds. |

||||||

COOLING WAFER: The adjustable feet on this AHP-1200CP Peltier cooling plate (thermoelectric cooling plate) made life easier on the factory floor.

Customer wafers needed cooling at the end of processing and the feet brought the cold plate up to the perfect height to match the production mechanisms. Just a little option that TECA is ready to provide to make the products we build work for you. |

||||||

MANUFACTURING:

Here’s another example of an AHP-1200CP thermoelectric cooler plate (Peltier cooler plate) used in a manufacturing station. The adjustable feet provide vertical flexibility in lining up the cold plate with the workstation. Parts slide easily from the hot plate to the work surface to the cold plate. |

||||||

|

The AHP-301CP Cold Plate has simplified the customer’s process by replacing a messy hot wax system.

A customer heard about TECA’s Thermoelectric Cold Plates through word-of-mouth and placed an order within the week. The AHP-301CP Cold Plate is used in the customer’s 3D printing process. Parts are printed on an aluminum plate which is then set on the AHP-301CP Cold Plate. As the AHP-301CP Cold Plate cools the aluminum plate, the 3D prints just pop right off of the aluminum plate. The customer is pleased with the performance, ease of use and low purchase price of this basic model. |

||||||

COOLING LED CHIPS:

The customer was looking for a cooling solution for LED chips. With a heat load as high as 45 watts at times, |

||||||

|

Our customer asked for a quote on delivery and price for the LHP-800CPHC. He then asked if we had a liquid cooled version of the AHP-1200CPHC (15" x 7.3" plate)?

The product had been in the works but on the back burner. This customers request pulled it to the front. We offered an LHP1200CP. It would be liquid cooled with 15 x 7.3 cold plate requiring 24 VDC input.

The customer later set it up with a water pump and a radiator/fan arrangement to provide a recirculation cooling water path rather than connecting to the tap and sending it down the drain. |

||||||

INDUSTRIAL ADHESIVE COOLING:

These folks needed to cool a thick fluid that ends up being gaskets when robotically dispensed. A custom version of our AHP-1200CP fit the bill perfectly. Now the product is dispensed consistently because of the temperature control provided by thermoelectrics.

|

||||||

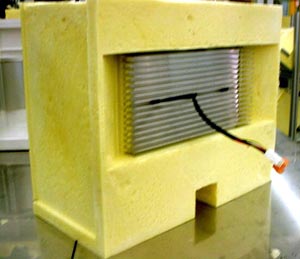

BEVERAGE COOLER: The application was to keep concentrated beverage container located next to a hot water tank cool in a high volume OEM application. TECA has always had the flexibility and resources to manufacture custom OEM thermoelectric cooler (peltier coolers) assemblies intended for use as part of a customer machine, apparatus, or system.

This OEM assembly is made by TECA in production runs in the thousands. It is not ours, so to protect the privacy and identity of our customers we can’t give too many details here. This assembly is part of a beverage service product which is shipped worldwide by a well known consumer products company. TECA furnishes the cooling "engine" which refrigerates the beverage product to be dispensed, and the OEM builds finished machinery in their own plants. |

||||||

Catalog | Sizing Software | Manuals | Applications | Site Map | Privacy Policy | Testimonials | Contact © 2014 ThermoElectric Cooling America Corporation. All Rights Reserved. |

||||||

trail and water and they needed to evaluate circuit boards @ various temperatures (-30C to -40C, no or minimal heat load, room temperature ambient) and on recommendation of a person who joined them from a controls company and had been using the solid state cold plate

trail and water and they needed to evaluate circuit boards @ various temperatures (-30C to -40C, no or minimal heat load, room temperature ambient) and on recommendation of a person who joined them from a controls company and had been using the solid state cold plate A global leader in developing and manufacturing cochlear implant systems uses the

A global leader in developing and manufacturing cochlear implant systems uses the